Ball Nosed Cylinder-C Diamond Grinding Head-Cut Tools

Foto Item

Rincian dhasar item

Advantage: 1. materi Diamond, ora gampang deform.2. Kurang bledug, luwih akeh perlindungan lingkungan.3. Baja mangan dhuwur, matriks kenthel.4. Rod penguat dirancang kanggo ndawakake umur layanan.

Jeneng Item: Diamond Grinding Head

Model barang: Ball Nosed Cylinder-C

Bahan Kepala: Diamond

Aplikasi item:

1. Bagian cetakan digiling lan dipoles.

2. Grinding: umume digunakake kanggo mecah burr saka workpiece, utawa mesin lumahing workpiece karo tliti kurang Gunakake mesin mecah, listrik, pneumatik lan pribadi liyane kanggo operate ing kacepetan dhuwur kanggo entuk efek mecah.

3. Polishing: iki khusus digunakake kanggo Processing karo syarat dhuwur kanggo Rampung lumahing (roughness).Iki minangka proses sing mbutuhake pangolahan sing kapisah.

Diameter Kepala: 6mm/8mm/12mm/14mm/16mm/18mm/20mm

Dawane sirah: 27mm

Dawane Shank: 33mm

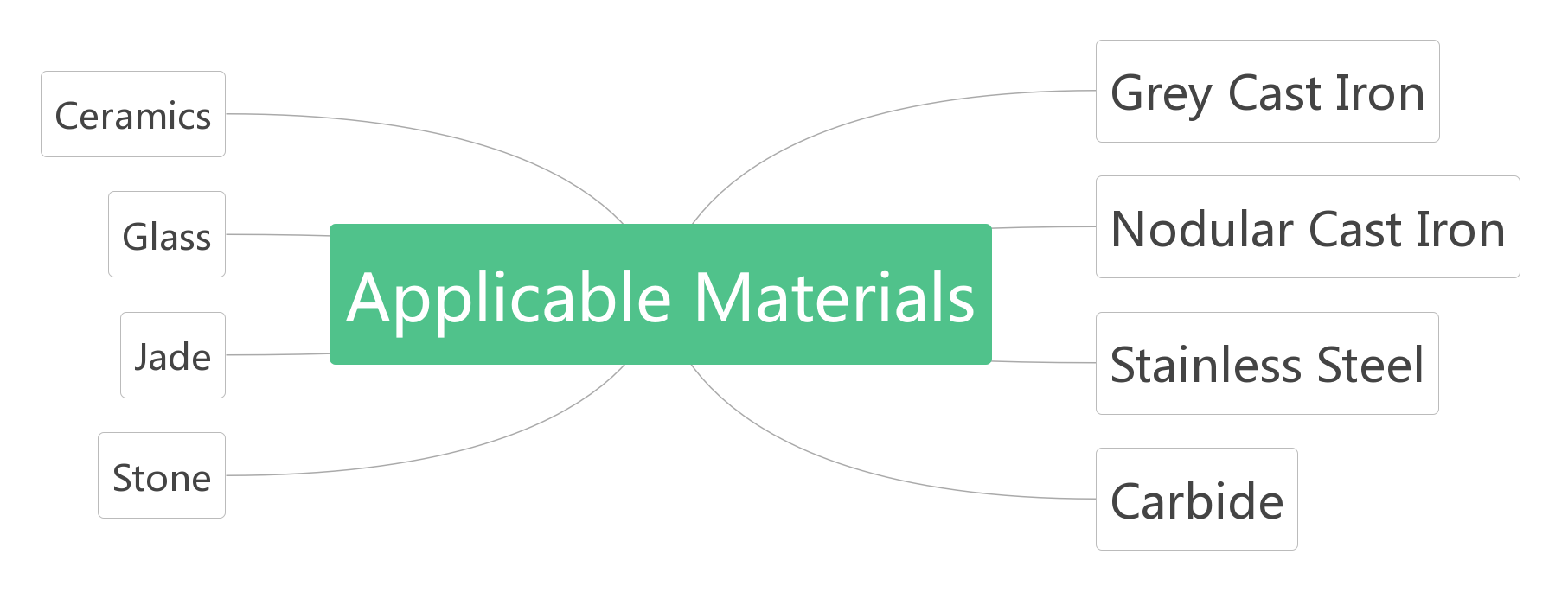

Item Materi sing Ditrapake

Aplikasi Item

1. Pengolahan watu

2. Pengolahan kaca

3. Klamben gembong grinding, bahan refractory, produk semen

4. Gunakake kanggo mecah, polishing lan grinding6.Bagian jamur wis lemah lan polesan

5. Biasane dipasang ing grinders, grinders, polishers, utawa piranti instalasi khusus.Iki digunakake kanthi wiyar ing lensa optik, prisma, kaca arloji, kaca safir.

Dimensi Item

| Model | Dhiameter | Total Length | Dawane Kerja | Panjang Shank | Diameter Shank |

| Ball Nosed Silinder 6*6 | 6 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*8 | 8 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*10 | 10 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*12 | 12 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*14 | 14 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*16 | 16 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*18 | 18 mm | 60 mm | 27 mm | 33 mm | 6 mm |

| Ball Nosed Silinder 6*20 | 20 mm | 60 mm | 27 mm | 33 mm | 6 mm |

Skenario sing ditrapake

Perbandingan Produk

Brazing grinding sirah

● Urip layanan dawa, luwih awet tinimbang kepala grinding biasa

● Kurang bledug, luwih ramah lingkungan

● mecah Sharp lan efficiency dhuwur

● Baja mangan dhuwur, matriks kenthel

Kepala penggilingan tradisional

● Urip layanan sing cendhak, stres sing ora rata bakal ngasilake deformasi

● Lebu gedhe, nyebabake cilaka kanggo awak manungsa

● urip layanan Short, panggantos manual iku wektu-akeh lan laborious

● Gagang bahan biasa, gampang pecah, keseimbangane kurang

Kaluwihan produk

1. We are profesional carbide burr Produsèn wiwit 1992. Kanthi 30 taun mecah produk saka pengalaman.

2. Kita bakal nguji kabeh produk kanthi ketat.

3. Kabeh produk ing Simpenan.

4. Kita nyedhiyakake logo shank gratis lan label gratis ing produk.

Diamond Grinding Kepala Kaluwihan

1. Efisiensi mecah dhuwur:

Nalika mecah karbida semen, efisiensi penggilingan kasebut kaping pirang-pirang tinimbang silikon karbida.Nalika nggiling W12 cr4v4mo, baja kacepetan dhuwur kanthi kinerja grinding sing kurang, efisiensi rata-rata tambah luwih saka 5 kaping.

2. tahan nyandhang dhuwur:

Diamond grinding wheel duwe resistance nyandhang dhuwur lan konsumsi abrasive kurang, utamané nalika mecah workpieces hard lan brittle.Nalika mecah baja quenched karo diamond mecah wheel, resistance nyandhang iku 100 ~ 200 kaping saka abrasive umum;

3. Workpiece mecah wis tliti dhuwur lan kualitas lumahing apik

Nalika nggiling alat karbida cemented karo rodha mecah berlian, roughness saka lumahing agul-agul lan agul-agul luwih murah tinimbang karo borax carbide wheel.Radius busur saka lading cilik, lan lading banget landhep.Daya tahan alat kasebut bisa ditambah 1-3 kaping.The roughness saka workpiece diproses dening diamond grinding wheel umume bisa tekan 0.1 ~ 0.025 μm.Dibandhingake karo grinding wheel grinding biasa, finish bisa ditingkatake dening 1 ~ 2 tingkat.